PU-40 UV Resistance Weather proof Construction Polyurethane Sealant

Applications

Sealing of expansion and settlement joint of house building, plaza, road, airport runway, anti- all, bridges and tunnels, building doors and windows etc.

Sealing of upstream face crack of drainage pipeline, drains, reservoirs, sewage pipes, tanks, silos etc.

Sealing of through holes on various wall and at floor concrete.

Sealing of joints of prefab, side fascia, stone and color steel plate, epoxy floor etc.

Attention of operation

Wear suitable protective clothing, gloves and eye/face Protection. After contact with skin, wash immediately with plenty of water and soap. In case of accident or if you feel unwell, seek medical advice immediately.

Warranty and Liability

All product properties and application details based on information are ensured to be reliable and accurate. But you still need to test its property and safety before application. All advices we supply can’t be applied in any circumstances.

CHEMPU don't make assurance of any other applications outside the specification until CHEMPU supply a special written guarantee.

CHEMPU is only responsible to replace or refund if this product is defective within the warranty period stated above.

CHEMPU makes it clear that will not take responsible for any accidents.

|

PROPERTY PU-40 |

|

|

Appearance |

Black/Grey/White Paste Uniform Sticky Liquid |

|

Density (g/cm³) |

1.35±0.05 |

|

Tack Free Time (Hr) |

≤180 |

|

Tensile modulus(MPa) |

≤0.4 |

|

Hardness (Shore A) |

35±5 |

|

Curing Speed (mm/24h) |

3 ~ 5 |

|

Elongation at Break (%) |

≥600 |

|

Solid Content (%) |

99.5 |

|

Operation Temperature ( ℃) |

5-35 ℃ |

|

Service Temperature ( ℃) |

-40~+80 ℃ |

|

Shelf Life (Month) |

9 |

|

Implementation of standards: JT/T589-2004 |

|

StorageNotice

1. Sealed and stored in cool and dry place.

2. It is suggested to be stored at 5~25 ℃, and the humidity is less than 50%RH.

3. If the temperature is higher than 40 ℃ or the humidity is more than 80%RH, the shelf life may be shorter.

Packing

310ml Cartridge

400ml/600ml Sausage

20pcs/Box, 2 Boxes in a Carton

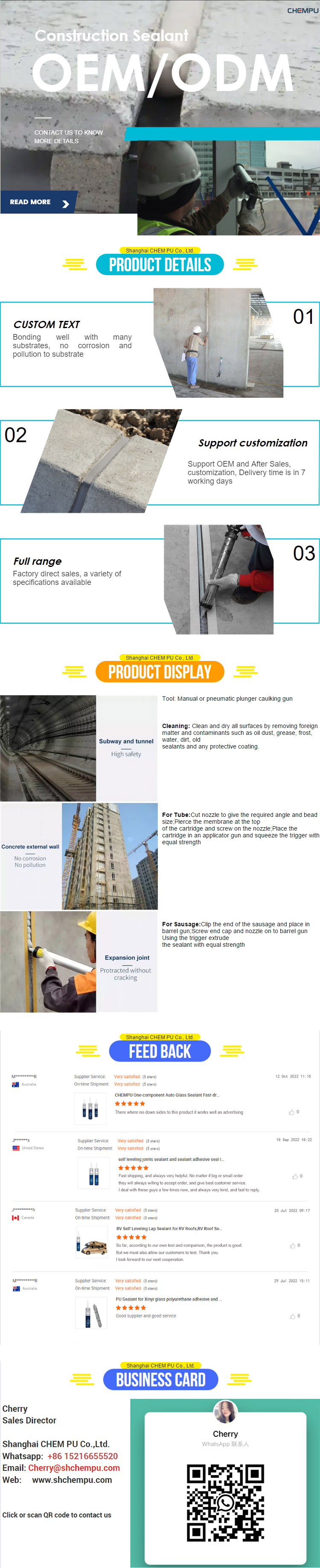

Tool: Manual or pneumatic plunger caulking gun

Cleaning: Clean and dry all surfaces by removing foreign matter and contaminants such as oil dust, grease, frost, water, dirt, old sealants and any protective coating.

For cartridge

Cut nozzle to give the required angle and bead size

Pierce the membrane at the top of the cartridge and screw on the nozzle

Place the cartridge in an applicator gun and squeeze the trigger with equal strength

For sausage

Clip the end of the sausage and place in barrel gun

Screw end cap and nozzle on to barrel gun

Using the trigger extrude the sealant with equal strength