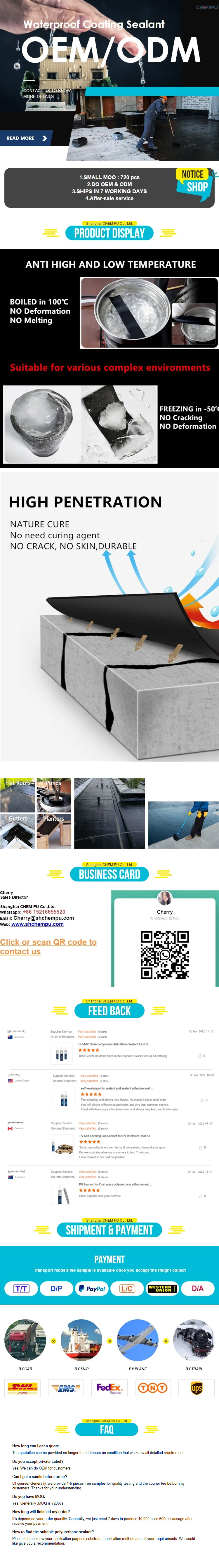

MS-001 New type MS Waterproof Coating

Applications

Waterproofing and moisture proofing for kitchen, bathroom, balcony, roof and so on.

Anti-seepage of reservoir, water tower, water tank, swimming pool, bath, fountain pool, sewage treatment pool and drainage irrigation channel.

Leak-proofing and anti-corrosion for ventilated basement, underground tunnel, deep well and underground pipe and so on.

Bonding and moisture proofing of all kinds of tiles, marble, wood, asbestos and so on.

Warranty and Liability

All product properties and application details based on information are ensured to be reliable and accurate. But you still need to test its property and safety before application. All advices we supply can’t be applied in any circumstances.

CHEMPU don't make assurance of any other applications outside the specification until CHEMPU supply a special written guarantee.

CHEMPU is only responsible to replace or refund if this product is defective within the warranty period stated above.

CHEMPU makes it clear that will not take responsible for any accidents.

|

PROPERTY JWS-001 |

|

|

Appearance |

White, Grey Uniform Sticky Liquid |

|

Density (g/cm³) |

1.35±0.1 |

|

Tack Free Time (Min) |

40 |

|

Adhesion Elongation |

>300 |

|

Tensile Strength(Mpa) |

>2 |

|

Curing Speed (mm/24h) |

3 ~ 5 |

|

Elongation at Break (%) |

≥1000 |

|

Solid Content (%) |

99.5 |

|

Operation Temperature ( ℃) |

5-35 ℃ |

|

Service Temperature ( ℃) |

-40~+120 ℃ |

|

Shelf Life (Month) |

12 |

Storage Notice

1.Sealed and stored in cool and dry place.

2.It is suggested to be stored at 5~25 ℃, and the humidity is less than 50%RH.

3.If the temperature is higher than 40 ℃ or the humidity is more than 80%RH, the shelf life may be shorter.

Packing

20kg/Pail , 230kg/Drum

Preparation for Operation

1. Tools: The serrated plastic board, brush, plastic barrels, 30Kg electronics, rubber gloves and cleaning tools like blade .etc.

2. Environmental requirements:The temperature is 5~35 C and the humidity is 35 ~ 85%RH.

3. Cleaning:The substrate surface must be solid, dry and be clean. Such as no dust, grease, asphalt, tar, paint, wax, rust, water repellent, curing agent, isolating agent and film. Surface cleaning can be dealt with by removing, cleaning, blowing, and so on.

4.Make the substrate surface level:If there are cracks on the substrate surface, first step is to fill them, and the surface should be leveled. Operation after the sealant curing more than 3mm.

5.Theoretical dosage: 1.0mm thick, 1.3 Kg /㎡ coating needed.

Operation

First Step

Brushing the part like corner, tubes root. When operation,It should be considered about the size, shape and environment of the construction area.

Second Step

Symmetrical scraping. The best thickness of the coating is no more than 2mm to prevent the bubbles.

Protection:

If necessary,a proper protective layer can be operated on the surface of the coating

Attention of operation

Wear suitable protective clothing, gloves and eye/face protection. After contact with skin, wash immediately with plenty of water and soap. In case of accident or if you feel unwell, seek medical advice immediately.